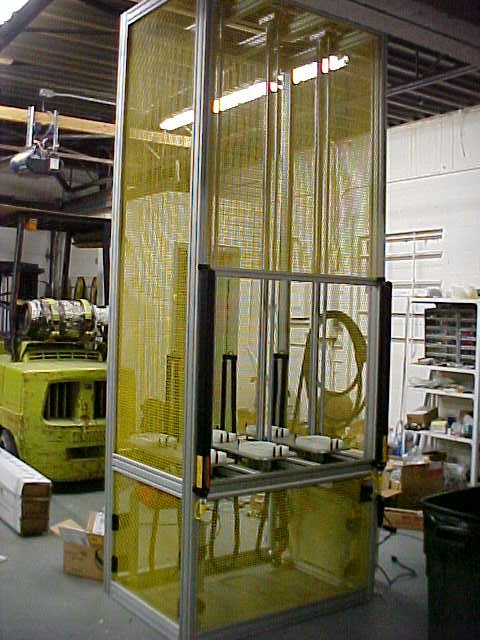

Insert molding can be accomplished by a robotic End Of Arm Tool (EOAT) attached to the customers robot and a loading station. The application pictured above is an in-mold transfer operation. An operator loads inserts at floor level and they are then elevated to the robot that is mounted on top of the molding machine. The robot retreives inserts from the loading station, loads them onto the "A" side of the mold, picks all four cavities from the "B" side of the mold, and transfers the first shot parts into the second shot cavities. The finished parts are deposited onto the same nest that held the inserts. The elevator lowers the finished parts to the operator.